Polyurethane Insulation Pipe Fittings: Elevating Performance in Chemical Processing

Release time:

2025-05-03

Polyurethane Insulation Pipe Fittings: Enhancing Performance in Chemical Processing Table of Contents Introduction to Polyurethane Insulation Pipe Fittings The Importance of Insulation in Chemical Processing Benefits of Polyurethane Insulation Pipe Fittings Energy Efficiency Superior Thermal Performance Moisture Resistance and Durability

Polyurethane Insulation Pipe Fittings: Enhancing Performance in Chemical Processing

Table of Contents

- Introduction to Polyurethane Insulation Pipe Fittings

- The Importance of Insulation in Chemical Processing

- Benefits of Polyurethane Insulation Pipe Fittings

- Applications of Polyurethane Insulation Pipe Fittings

- Installation Guidelines for Optimal Performance

- Maintenance Tips for Longevity

- Sustainability and Environmental Considerations

- The Future of Polyurethane Pipe Fittings in Chemical Processing

- Conclusion

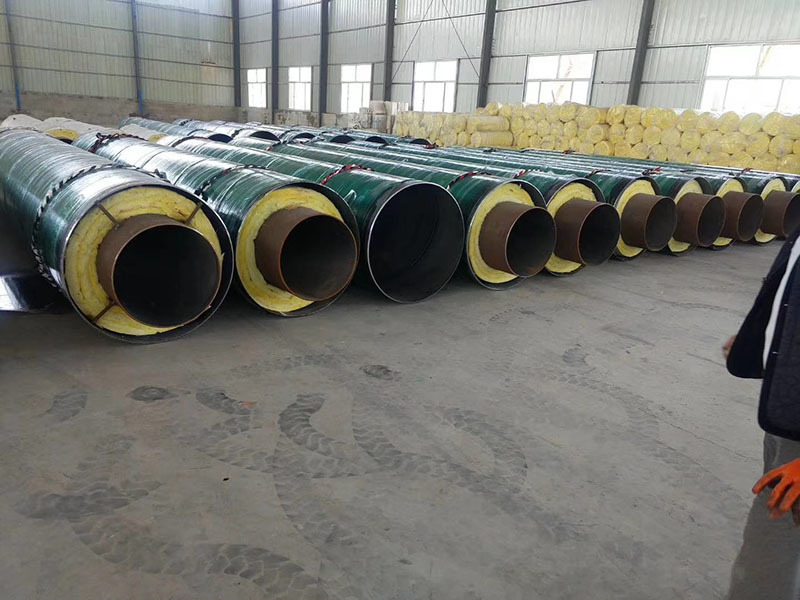

Introduction to Polyurethane Insulation Pipe Fittings

Polyurethane insulation pipe fittings have emerged as a crucial component in the chemical processing industry. They provide not only an effective means of insulation but also contribute to the overall efficiency and safety of various processes. In this article, we will delve deep into the numerous advantages these fittings offer, their applications, and their importance in enhancing performance within chemical processing facilities.

The Importance of Insulation in Chemical Processing

Effective insulation is paramount in chemical processing. The right insulation can significantly reduce energy costs, maintain optimal operating temperatures, and protect sensitive materials from temperature fluctuations. A well-insulated system is less prone to failure, ensuring a more reliable operation. This section will explore why high-quality insulation, such as polyurethane, is indispensable in today’s industrial settings.

Energy Savings and Cost Reduction

The primary advantage of insulation is its ability to save energy. In chemical processing, maintaining the correct temperature is vital for efficiency and product quality. By insulating pipes and fittings with polyurethane, companies can reduce heat loss, leading to lower energy consumption and significant cost savings over time.

Protection Against Temperature Fluctuations

Chemical processes often involve extreme temperatures. Insulation helps maintain these temperatures, protecting raw materials and finished products from degradation. Polyurethane’s thermal stability ensures that processes remain consistent, further enhancing product quality.

Benefits of Polyurethane Insulation Pipe Fittings

Polyurethane insulation pipe fittings offer a plethora of benefits that make them an essential choice in chemical processing. Their unique properties contribute to enhanced performance and reliability.

Energy Efficiency

Polyurethane insulation is known for its high R-value, which indicates its thermal resistance. This characteristic allows for superior energy efficiency, minimizing the amount of energy required to maintain temperatures. Industries can achieve a rapid return on investment when energy costs decrease due to improved insulation.

Superior Thermal Performance

Polyurethane insulation excels in thermal performance due to its closed-cell structure. This structure minimizes heat transfer, ensuring that pipes remain at the desired temperature. Moreover, polyurethane’s lightweight nature makes it easier to handle and install, further streamlining processes.

Moisture Resistance and Durability

Moisture can severely impact the performance of insulation materials. Polyurethane is inherently moisture-resistant, preventing issues such as mold growth and thermal inefficiency. This durability makes it suitable for a variety of environments, including those with high humidity levels.

Applications of Polyurethane Insulation Pipe Fittings

Polyurethane insulation pipe fittings find applications across various sectors within chemical processing, including:

1. Oil and Gas Industry

In the oil and gas sector, these fittings are vital for maintaining the temperature of pipelines transporting heated or chilled substances. Proper insulation prevents energy loss and ensures safe transportation.

2. Chemical Manufacturing

Chemical plants utilize polyurethane fittings to insulate pipes that carry volatile substances. This insulation minimizes the risk of leaks and enhances safety during transport.

3. Food and Beverage Processing

In the food industry, maintaining strict temperature controls is essential. Polyurethane insulation helps preserve the quality of food products by preventing temperature fluctuations.

Installation Guidelines for Optimal Performance

To maximize the benefits of polyurethane insulation pipe fittings, proper installation is crucial. Here are some essential guidelines:

Site Preparation

Before installation, ensure that the surface of the pipes is clean and dry. Any contaminants can compromise the effectiveness of the insulation.

Proper Fitting

Choose the correct size of polyurethane fittings to ensure a snug fit. Gaps can lead to heat loss and moisture intrusion, negating the benefits of insulation.

Sealing Joints

Use high-quality sealants to secure joints between the fittings and pipes. This step is essential to prevent any heat loss and maintain system efficiency.

Maintenance Tips for Longevity

To ensure the longevity and effectiveness of polyurethane insulation pipe fittings, regular maintenance is necessary. Here are some tips:

1. Routine Inspections

Conduct regular inspections to identify any signs of wear or damage. Early detection allows for timely repairs, preventing further issues.

2. Cleaning

Keep the fittings clean and free from debris. Accumulated dirt can trap moisture and reduce insulation effectiveness.

3. Monitoring Temperature

Regularly monitor the temperature of the pipes. Significant fluctuations may indicate insulation failure or other system issues.

Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in industrial processes. Polyurethane insulation pipe fittings align with this trend due to their energy efficiency and long lifespan. By reducing energy consumption, they contribute to lower carbon emissions, making them an environmentally friendly choice for chemical processing.

The Future of Polyurethane Pipe Fittings in Chemical Processing

As industries strive for greater efficiency and sustainability, the role of polyurethane insulation pipe fittings will only become more significant. Innovations in material science may lead to even more advanced insulation solutions, further enhancing their performance and application scope. Companies that invest in these technologies will likely gain a competitive edge in the market.

Conclusion

Polyurethane insulation pipe fittings represent a vital component in the chemical processing industry, offering unparalleled benefits in energy efficiency, thermal performance, and durability. Their applications span various sectors, ensuring safe and efficient operations. As we look to the future, embracing these innovative solutions will be essential for achieving sustainability and enhancing overall process performance. By understanding and implementing the advantages of polyurethane insulation, businesses can secure their place at the forefront of the chemical processing industry.

FAQs

1. What are polyurethane insulation pipe fittings made of?

Polyurethane insulation pipe fittings are made from a polymer-based material known for its superior thermal insulation properties and moisture resistance.

2. How do polyurethane fittings enhance energy efficiency?

Their high R-value minimizes heat loss, reducing the energy required to maintain operational temperatures in chemical processes.

3. Can polyurethane insulation withstand extreme temperatures?

Yes, polyurethane insulation performs well at both high and low temperatures, making it suitable for a variety of chemical processing applications.

4. Are polyurethane insulation pipe fittings environmentally friendly?

Yes, they contribute to energy savings and reduced carbon emissions, making them a sustainable choice for industrial applications.

5. How often should I inspect polyurethane insulation fittings?

Regular inspections should be conducted at least twice a year to ensure optimal performance and identify any potential issues early.

keyword:

Related News