Sustainability at its Best: Inner Epoxy Outer Polyurethane Pipes - The Ultimate Solution for Modern Construction

Release time:

2025-06-12

Sustainability at its Best: Inner Epoxy Outer Polyurethane Pipes Table of Contents Introduction to Inner Epoxy Outer Polyurethane Pipes What Are Inner Epoxy Outer Polyurethane Pipes? Benefits of Inner Epoxy Outer Polyurethane Pipes 1. Durability and Longevity 2. Eco-Friendly Properties 3. Cost-Effectiveness Applications of Inner Epoxy Outer Polyurethane P

Sustainability at its Best: Inner Epoxy Outer Polyurethane Pipes

Table of Contents

- Introduction to Inner Epoxy Outer Polyurethane Pipes

- What Are Inner Epoxy Outer Polyurethane Pipes?

- Benefits of Inner Epoxy Outer Polyurethane Pipes

- Applications of Inner Epoxy Outer Polyurethane Pipes

- Installation and Maintenance of Inner Epoxy Outer Polyurethane Pipes

- The Future of Inner Epoxy Outer Polyurethane Pipes

- Frequently Asked Questions (FAQs)

- Conclusion

Introduction to Inner Epoxy Outer Polyurethane Pipes

As the world increasingly shifts towards sustainable practices, the construction and decoration materials industry is witnessing significant advancements. Among these innovations, **inner epoxy outer polyurethane pipes** stand out as a paradigm shift in material usage. Not only do they offer enhanced durability and performance, but they also respond to the growing demand for eco-friendly solutions.

This article explores the myriad advantages of using these pipes, their applications in various sectors, and how they contribute to sustainable construction practices.

What Are Inner Epoxy Outer Polyurethane Pipes?

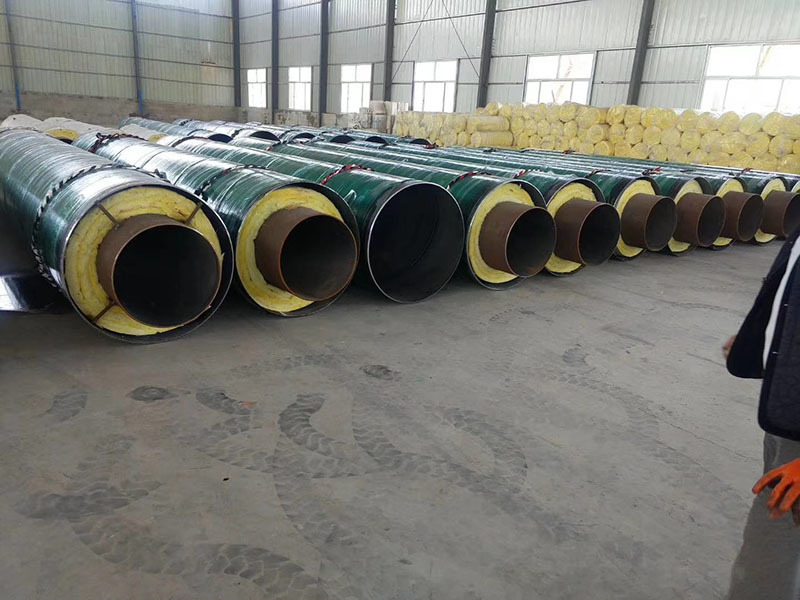

Inner epoxy outer polyurethane pipes are engineered pipes designed with a unique composition. The inner layer consists of epoxy resin, providing a robust barrier against corrosion, chemicals, and wear. The outer layer is made from polyurethane, which enhances flexibility, impact resistance, and weatherability. This combination creates a pipe that is not only functional but also versatile, catering to a range of applications in the construction and industrial sectors.

These pipes are a response to traditional piping systems that often fall short in durability and sustainability. By utilizing advanced materials, inner epoxy outer polyurethane pipes deliver a performance that outperforms conventional options, establishing themselves as a go-to choice for modern projects.

Benefits of Inner Epoxy Outer Polyurethane Pipes

Utilizing inner epoxy outer polyurethane pipes comes with a plethora of benefits. Below, we dissect some of the most significant advantages that these pipes bring to the table.

1. Durability and Longevity

One of the most compelling reasons to choose inner epoxy outer polyurethane pipes is their remarkable durability. The epoxy layer protects against corrosion and chemical reactions, extending the lifespan of the pipes significantly. Furthermore, the polyurethane outer layer is resistant to abrasion and impact, making these pipes suitable for harsh environments.

In comparison to traditional pipes, which may require frequent replacements, these advanced pipes can withstand extreme conditions, thereby offering a long-term solution for infrastructure projects.

2. Eco-Friendly Properties

Sustainability is at the core of the design of inner epoxy outer polyurethane pipes. The materials used in their construction are often recyclable, reducing waste and environmental impact. Additionally, their longevity translates to less frequent replacement and lower resource consumption over time.

Moreover, the manufacturing process of these pipes typically involves less energy compared to traditional options, further enhancing their eco-friendly profile. By choosing inner epoxy outer polyurethane pipes, builders and developers can contribute to a greener future.

3. Cost-Effectiveness

Though the initial investment in inner epoxy outer polyurethane pipes may be higher than conventional materials, the long-term savings they offer are substantial. Their durability means fewer replacements, less maintenance, and lower installation costs over time. Additionally, their resistance to wear reduces the likelihood of costly downtime for repairs.

In summary, opting for these pipes is not just a sustainable choice; it is also a financially savvy decision for businesses looking to optimize their expenses.

Applications of Inner Epoxy Outer Polyurethane Pipes

The versatility of inner epoxy outer polyurethane pipes makes them suitable for a broad range of applications across various industries. Below are some key areas where these pipes excel.

1. Construction Industry

In the construction sector, inner epoxy outer polyurethane pipes are gaining traction for their ability to handle both above-ground and underground applications. Their robustness makes them ideal for structural support, drainage systems, and even as conduits for electrical wiring.

Furthermore, their eco-friendly composition aligns perfectly with the growing trend towards sustainable building practices, making them an attractive choice for modern construction projects.

2. Water Management Systems

Water management is a critical aspect of urban infrastructure, and inner epoxy outer polyurethane pipes play a vital role in this domain. Their corrosion resistance and leak-proof nature make them excellent for water distribution and sewage systems.

These pipes not only ensure safe transport of potable water but also reduce the risk of contamination, contributing to public health and environmental protection.

3. Industrial Use Cases

In industrial settings, inner epoxy outer polyurethane pipes are utilized for transporting chemicals, gases, and other hazardous materials. Their ability to withstand extreme temperatures and pressures makes them ideal for a variety of applications, including oil and gas pipelines, chemical processing plants, and more.

The reliability and safety features of these pipes enhance operational efficiency, making them indispensable in many industrial processes.

Installation and Maintenance of Inner Epoxy Outer Polyurethane Pipes

Successful implementation of inner epoxy outer polyurethane pipes requires careful installation and ongoing maintenance. Understanding these processes can optimize their performance and longevity.

1. Installation Process

Installing inner epoxy outer polyurethane pipes involves several key steps:

1. **Site Preparation**: Ensure the installation area is clean and free of debris.

2. **Trenching**: Dig trenches to accommodate the pipes, ensuring they are deep enough to prevent exposure to external elements.

3. **Pipe Placement**: Lay the pipes in the trench while ensuring proper alignment and slope for drainage.

4. **Connection**: Use appropriate fittings to connect sections of the pipe, ensuring a tight seal to prevent leaks.

5. **Backfilling**: Once installed, backfill the trench carefully to avoid damaging the pipes.

Following these steps ensures optimal performance and durability of the piping system.

2. Maintenance Tips

While inner epoxy outer polyurethane pipes are designed to require minimal maintenance, regular checks can prevent unexpected issues. Here are some tips:

- **Routine Inspections**: Conduct periodic visual inspections for any signs of wear, corrosion, or leaks.

- **Cleaning**: Remove any debris or buildup on the exterior to maintain the integrity of the pipes.

- **Pressure Testing**: Perform pressure tests to ensure the pipes can withstand operational demands.

By adhering to these maintenance practices, the lifespan of the pipes can be extended, ensuring continued efficiency.

The Future of Inner Epoxy Outer Polyurethane Pipes

The future of inner epoxy outer polyurethane pipes appears promising, fueled by the increasing demand for sustainable building materials. As technology advances, manufacturers are likely to improve the efficacy and functionality of these pipes, making them even more appealing to various industries.

Innovative applications, such as smart piping systems equipped with sensors to monitor flow and detect leaks, may soon be on the horizon, further enhancing their role in modern infrastructure.

Frequently Asked Questions (FAQs)

1. How long do inner epoxy outer polyurethane pipes last?

The lifespan of these pipes can exceed 50 years when properly installed and maintained, making them a durable investment.

2. Are inner epoxy outer polyurethane pipes environmentally friendly?

Yes, these pipes are made from recyclable materials and produced with energy-efficient processes, contributing to their eco-friendliness.

3. Can these pipes be used for both hot and cold water systems?

Yes, inner epoxy outer polyurethane pipes can handle a range of temperatures, making them suitable for various water systems.

4. What is the cost difference compared to traditional pipes?

While the initial cost may be higher, the long-term savings from reduced maintenance and replacement make them a cost-effective choice.

5. Are there any restrictions on the use of these pipes?

Usage may be subject to local building codes and regulations, so it is essential to check with local authorities before installation.

Conclusion

Inner epoxy outer polyurethane pipes represent a significant advancement in construction and decoration materials, combining sustainability with unparalleled performance. Their durability, eco-friendly properties, and versatility make them ideal for a wide range of applications. As industries continue to prioritize sustainability, these innovative pipes are likely to play a pivotal role in shaping the future of construction.

By investing in inner epoxy outer polyurethane pipes, builders and developers not only enhance the quality of their projects but also contribute positively to the environment, paving the way for a more sustainable future.

keyword:

Previous article

Related News