Efficiency Redefined: The Impact of Buried Polyurethane Insulation Pipes on Modern Building Design

Release time:

2025-06-22

Efficiency Redefined: The Impact of Buried Polyurethane Insulation Pipes on Modern Building Design Table of Contents 1. Introduction to Buried Polyurethane Insulation Pipes 2. What Are Buried Polyurethane Insulation Pipes? 3. Benefits of Using Buried Polyurethane Insulation Pipes 3.1 Energy Efficiency and Cost Savings 3.2 Enhanced Thermal Management

Efficiency Redefined: The Impact of Buried Polyurethane Insulation Pipes on Modern Building Design

Table of Contents

- 1. Introduction to Buried Polyurethane Insulation Pipes

- 2. What Are Buried Polyurethane Insulation Pipes?

- 3. Benefits of Using Buried Polyurethane Insulation Pipes

- 4. Installation Process of Buried Polyurethane Insulation Pipes

- 5. Sustainability and Environmental Impact

- 6. Case Studies: Successful Implementation

- 7. Future Trends in Building Design and Insulation

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Buried Polyurethane Insulation Pipes

The construction industry constantly seeks innovative solutions to enhance energy efficiency and sustainability. Buried polyurethane insulation pipes represent a significant advancement in this field. These pipes offer various advantages that can redefine modern building design, making them a crucial consideration for architects and builders aiming to create energy-efficient structures.

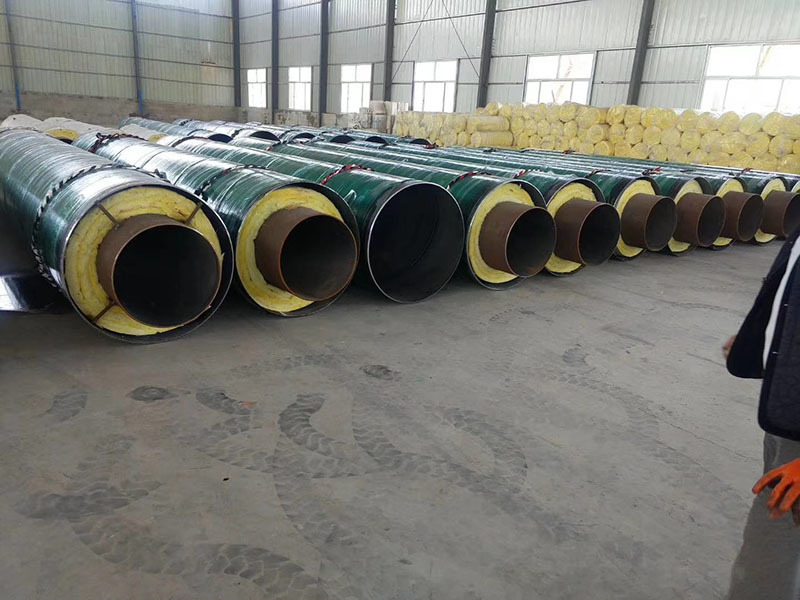

2. What Are Buried Polyurethane Insulation Pipes?

Buried polyurethane insulation pipes are insulated piping systems designed for underground installation. Made from high-performance polyurethane, these pipes provide effective thermal insulation. Their design reduces heat loss in heating and cooling systems, making them ideal for various applications, from residential to commercial buildings. The buried aspect allows for reduced exposure to environmental conditions, enhancing their performance and longevity.

3. Benefits of Using Buried Polyurethane Insulation Pipes

3.1 Energy Efficiency and Cost Savings

One of the primary advantages of buried polyurethane insulation pipes is their ability to significantly improve energy efficiency. By minimizing heat loss during the transmission of fluids, these pipes can contribute to lower energy consumption and reduced utility bills. Buildings utilizing these systems can achieve substantial savings over time, making them an economically viable option for energy-conscious projects.

3.2 Enhanced Thermal Management

Thermal management within a building is essential for maintaining comfort and efficiency. Buried polyurethane insulation pipes offer superior insulation properties, ensuring that the temperature of the fluids within the pipes remains stable. This stability translates to better climate control within buildings, which is particularly important in areas with extreme temperatures.

3.3 Durability and Longevity

Built to withstand harsh underground conditions, buried polyurethane insulation pipes possess exceptional durability. They resist corrosion, moisture, and physical stress, which extends their lifespan substantially compared to traditional materials. This longevity reduces the need for frequent replacements and maintenance, offering long-term cost savings for building owners.

4. Installation Process of Buried Polyurethane Insulation Pipes

The installation of buried polyurethane insulation pipes requires careful planning and execution. Here’s a step-by-step overview of the installation process:

1. **Site Assessment**: Conduct a thorough assessment of the installation site to determine the best locations for the pipes while considering factors such as soil conditions and existing infrastructure.

2. **Excavation**: Carefully excavate the designated areas for the pipes, ensuring that the trench dimensions meet the specifications outlined in the project plans.

3. **Pipe Placement**: Place the insulated pipes into the trench, ensuring they are aligned correctly and securely positioned.

4. **Backfilling**: Once the pipes are in place, backfill the trench with suitable materials to provide support and protection for the pipes.

5. **Testing and Inspection**: After installation, conduct pressure tests and inspections to ensure the integrity of the piping system before covering the installation site completely.

5. Sustainability and Environmental Impact

Sustainability is at the forefront of modern building design. Buried polyurethane insulation pipes boast eco-friendly properties, contributing to LEED certifications and other green building initiatives. Their energy-efficient nature helps reduce carbon footprints, while their durability minimizes waste from frequent replacements. Utilizing these pipes aligns with global efforts to promote sustainable construction practices.

6. Case Studies: Successful Implementation

Numerous projects have successfully incorporated buried polyurethane insulation pipes, showcasing their benefits:

- **Residential Complex in Urban Area**: A recent residential development in a densely populated urban area utilized buried polyurethane insulation pipes to significantly reduce heating costs. The result was a 30% decrease in energy consumption compared to similar buildings without this insulation.

- **Commercial Building Project**: A large commercial building project integrated these pipes into their heating systems. The implementation led to improved temperature regulation and a substantial reduction in energy waste, enhancing overall building performance.

7. Future Trends in Building Design and Insulation

As technology continues to evolve, the future of buried polyurethane insulation pipes looks promising. Innovations in materials and installation techniques are likely to emerge, further enhancing their efficiency and application versatility. Additionally, as the emphasis on sustainable building practices grows, these pipes will play a crucial role in meeting the demands of the modern construction industry.

8. Frequently Asked Questions

Q1: What makes polyurethane insulation pipes more effective than traditional insulation methods?

A1: Polyurethane insulation pipes offer superior thermal resistance, minimizing heat loss significantly compared to traditional insulation, leading to enhanced energy efficiency.

Q2: Can buried polyurethane insulation pipes be used in all climates?

A2: Yes, these pipes are designed to withstand various environmental conditions, making them suitable for use in different climates, including extreme weather conditions.

Q3: How long do buried polyurethane insulation pipes last?

A3: With proper installation and maintenance, these pipes can last for several decades, thanks to their durability and resistance to environmental stressors.

Q4: Are there any special maintenance requirements for these piping systems?

A4: Generally, buried polyurethane insulation pipes require minimal maintenance. Regular inspections can help identify any potential issues early on.

Q5: Are buried polyurethane insulation pipes environmentally friendly?

A5: Yes, these pipes contribute to energy efficiency and sustainability, aligning with eco-friendly building practices and reducing overall carbon footprints.

9. Conclusion

Buried polyurethane insulation pipes are redefining the standards of modern building design. With their impressive energy efficiency, enhanced thermal management, and remarkable durability, they present a compelling choice for architects and builders dedicated to sustainability and performance. As the construction industry continues to evolve, embracing these innovative materials will pave the way for creating energy-efficient and environmentally responsible structures that meet the demands of today's society.

keyword:

Previous article

Related News